HYDRO-KINETIC, a revolutionary septic system

NORWECO, leader in the development of Onsite products since 1906, offers the HYDRO-KINETIC, a compact, performant, affordable to operate and maintain treatment solution providing a long life expectancy and peace of mind. HYDRO-KINETIC is the right solution for homes, cottages or small commercial sites.

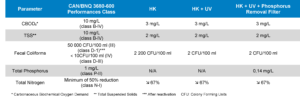

HYDRO-KINETIC is certified by the “Bureau de Normalisation du Québec” (BNQ) for standard NQ 3680-910 and CAN/BNQ 3680-600. HYDRO-KINETIC adapts to all types of sites regardless of its size or environmental sensitivity. HYDRO-KINETIC is certified for the following treatment levels:

- Advanced Secondary (class III and B-IV) for discharging toward a subsurface infiltration bed or a stream (subject to local regulation compliance);

- Tertiary – Disinfeciton (class V or D-II) for discharging towars a small stream or ditch (subject to local regulation compliance);

- Tertiaty – Phosphorus Removal (class IV or P-I) for discharging towards a lake

- Tertiary – Nitrogen Removal (Class N-I) for discharging into nitrogen sensitive environments.

Advantages

- Proven process assuring performance

- No septic tank required

- Robust and reliable components

- Lower maintenance fee

- Adapts to all types of dwellings

- Tested for Canadian cold climate

- Maintenance done by independant qualified technicians

- Only certified technology that accepts water softeners

HYDRO-KINETIC technical specifications

HYDRO-KINETIC compact and modular design as well as its two stages hybrid biological process, performances and ease of operation make it one of the best technology on the market. Its operation and maintenance cost are amongst the lowest in the industry considering its life expectancy that can reach way over 20 years. HYDRO-KINETIC owner can save thousands of dollars compared to other technologies.

No septic tank is required with the HYDRO-KINETIC and therefore no mandatory pumpouts are needed every 2 years (permanent homes) or 4 years (seasonnal homes) neither are additional fees added to your municipal taxes bill. Wastewater entering the HYDRO-KINETIC undergo two successive steps of primary treatment. First step is the capture of heavy soluids, oils, fats and greases in the pretreatment tank. Second step is the reduction of primary and secondary sludge through anaerobic and anoxic degradation in the anoxic compartment. Primary effuent then travels to the main bioreactor. Contrary to conventionnal septic tank requiring mandatory pumpouts, the pretreatment compartment of the HYDRO-KINETIC is only emptied when it reaches a certain level verified every year during our annual inspection. Average HYDRO-KINETIC owner can expect cutting in half its pumpout fees compared to other technologies. Over the lifespan of the system, this represents thousands of dollars saved by HYDRO-KINETIC owners.

The main treatment process is an hybrid biological reactor. The first part consists in a proven suspended growth extended aeration activated sludge process followed by clarification and recirculation of biomass. This step assures treatment of wastewater without the use of any media or clogging (occuring in most other types of systems). Once treated in this first stage, a final fixed film biofiltration is performed as the final stage of the hybid bioreactor to produce a highly treated final effluent. The synthetic media of this final stage does not clog and does not require any replacement or maintenance. This hybrid configuraiton is the key to the most mid to long term cost efficient system on the market.

One of the best avantage of the HYDRO-KINETIC is its sludge management. All systems produce primary and secondary sludges as it is the result of the degradation of the pollutant in wastewater. The HYDRO-KINETIC distinguishes itself from other technolgies on the way these sludges are produced and managed. In the first stage of the bioreactor responsible for about 90% of the performance, the bacteria achieving treatment are in suspension in the liquid phase where no media is present and no clogging can occur. When the biomass concentration reaches a level commanding a pumpout (notified following our annual inspection) which can take in average 8 to 10 years, this is done by simply emptying the tank using a septic tank pumper company. There is no media to clean, take out or replace. There is no more economical way to maintain a septic system. The only media of the HYDRO-KINETIC is in the final stage receiving already treated effluent. Therefore there is no clogging of this media and it does not require any maintenance. Other solutions offered in the market rely on a single biological treatment stage using a synthetic or organic media which every day clogs by accumulating treatment residus. These systems require periodic critical costly cleaning or complete media replacement otherwise the system would completetely clog and treatment capabilities would be impaired. For example, systems using organic filtering media such as coco husk or peat, require complete media replacement periodically and for the entire lifespan of the system. Other system using synthetic media such as plastic ribbon, sand or geotextile need periodic cleaning which is often complex and costly to take out the accumulated sludge captured within the media. Every time these cost add up to the global operation and maintenance fee of those technologies. HYDRO-KINETIC offering the most simple and economical way of managing treatment residues has enormous advantages on the mid to long term cost of your septic system.

The HYDRO-KINETIC is available in eight different models to meet your needs. The smallest unit is good for 1 to 3 bedrooms and the largest unit is capable of accomodating 6 bedrooms homes or more as well as small commercial sites.

Performances

Documentation

This product is available in Quebec, Ontario, Manitoba and Nova Scotia for commercial, institutional and community applications.